SORPAS® 3D is now officially launched after several years heavy research and developments. It is possible to simulate all complex and challenging applications of resistance welding.

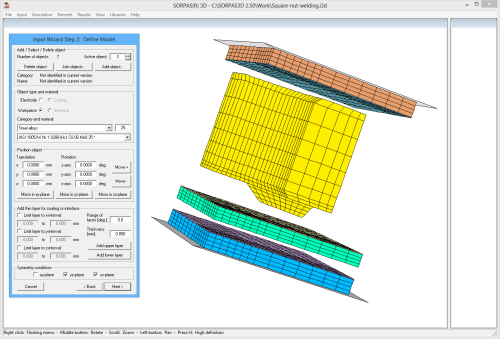

The design of SORPAS® 3D has continued on the same concept of SORPAS® 2D with easy-to-use graphic user interface (GUI) and straightforward functions for industrial applications of resistance welding. New Input Wizard has been specially developed for quickly building and operating 3D models, setting up welding process parameters, programming movements of electrodes and workpieces similar to operations in the assembly line of resistance welding. |

Demo CD for SORPAS® 3D

SORPAS® 3D version 3.0 Release Notes

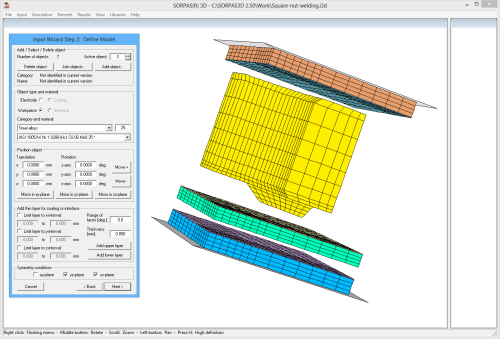

SORPAS® 3D can be quickly learned and used by industrial users and welding professionals. Below is a screenshot of the GUI with the step of Input Wizard for building 3D models.

The material database and machine database are directly shared from SORPAS® 2D. Two new libraries have been developed for storing and loading 3D models of hexahedral mesh objects for electrodes and workpieces.

Industrial applications of SORPAS® 3D:

SORPAS® 3D has been applied in various industries for simulation of complex welding applications of spot welding, projection welding, butt welding and micro resistance welding to facilitate and support research and development, product design, and welding process optimization. Below are some examples of SORPAS® 3D simulations.

|

|

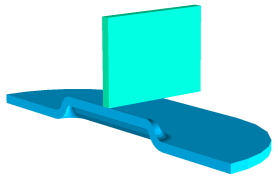

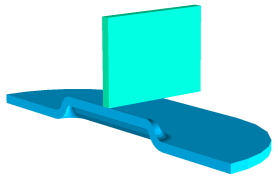

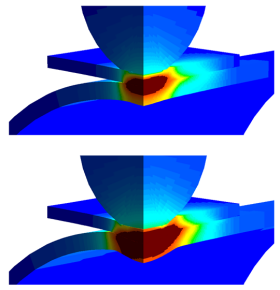

| SORPAS® 3D model for simulation of resistance projection welding with longitudinal embossment. |

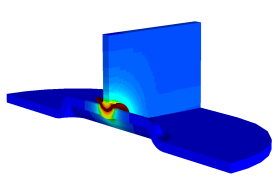

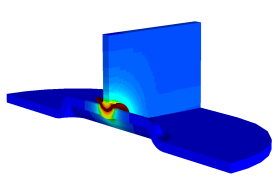

SORPAS® 3D simulation result for resistance projection welding with longitudinal embossment. |

|

|

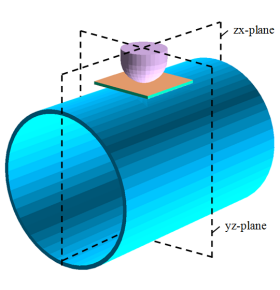

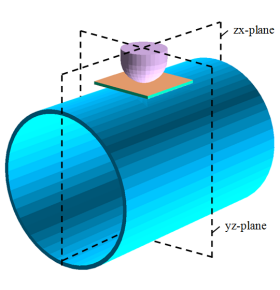

| SORPAS® 3D model for simulation of single-sided sheet to tube welding. |

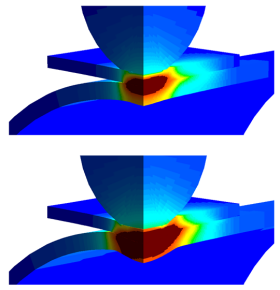

SORPAS® 3D simulation result for single-sided sheet to tube welding. |

SORPAS® 3D version 3.0 release notes with more cases of industrial applications.

|