Industries

Since first commercialized in 1999, SORPAS® has been continuously

developed and improved for industrial applications. It is now widely

used by leading manufacturing companies in various industrial

sectors all over the world, to support research and development,

weldability evaluation, welding process parameter optimization,

production line planning and launching, as well as maintenance in

resistance welding including spot welding and projection welding

etc.

The major industrial sectors applying resistance welding are listed

below. The major industrial sectors applying resistance welding are listed

below.

Some examples of applications in different industrial

sectors are presented in the sub-menu to the left and more cases

are shown in the Gallery of

case studies.

Welding process simulations:

|

|

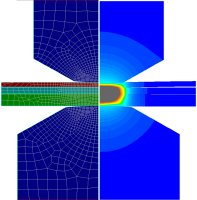

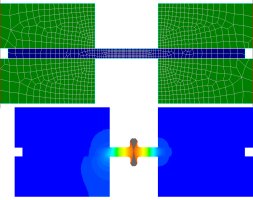

| Spot welding: Simulation of three-sheet

spot welding of low carbon steel, high strength low alloy (HSLA)

steel and Dual Phase (DP) steel sheets. |

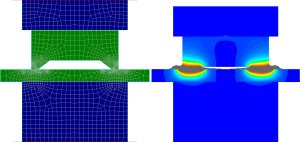

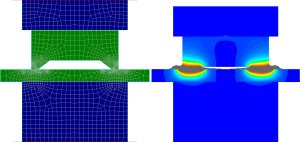

Projection welding: Simulation of projection welding of square nut with corner projections welded to steel sheet showing

the weld after collapse of the projections. |

| |

|

|

|

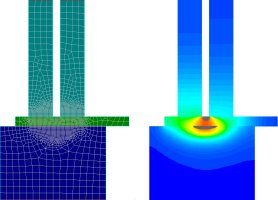

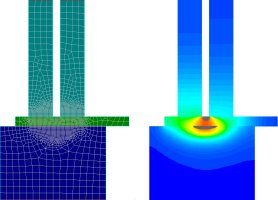

| Butt welding: Simulation of resistance butt welding of two steel plates welded at the ends with resistance heating and

subsequent forging and butt welding. |

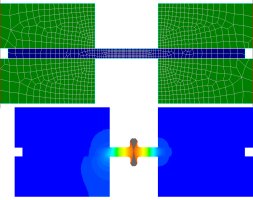

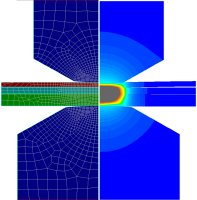

Parallel gap welding: Simulation of parallel gap welding

(micro resistance welding) for joining thin foil to substrate plate of

titanium alloys. |

Welding process parameter optimizations and process planning:

With the Enterprise Edition , several

functions for automated simulations have been developed to support

welding process parameter optimization. It is possible to run fully

automated procedures to generate the weld growth curves and the

weldability lobes.

|

|

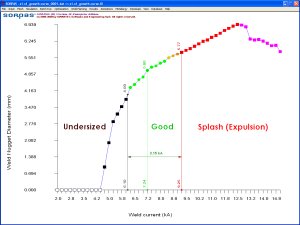

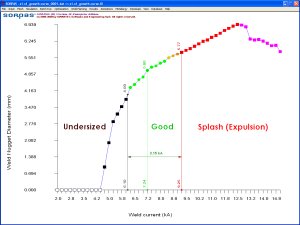

| This is a weld growth curve generated automatically with SORPAS®

for spot welding of 1 mm mild steel sheets in the range of weld

current from 2 kA to 15 kA. The software has automatically identified

the working range with green color points indicating the good

spot welds, the red color points indicating splashes and the

black color points indicating no weld. |

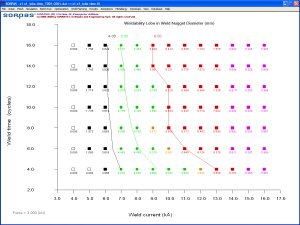

This is a weldability lobe generated automatically with SORPAS®

for spot welding of 1 mm mild steel sheets with two welding

process parameters (weld current and time) referring to ISO

14327:2004. Three reference weld nugget diameters (minimum,

maximum and nominal) are indicated. It is also possible to generate

the weldability lobe with weld current and force. |

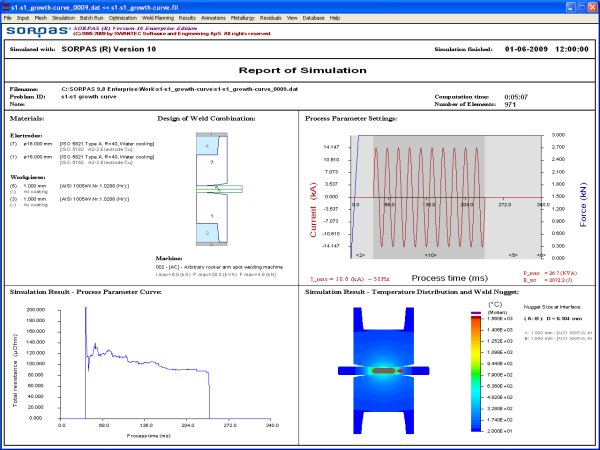

Report of simulation:

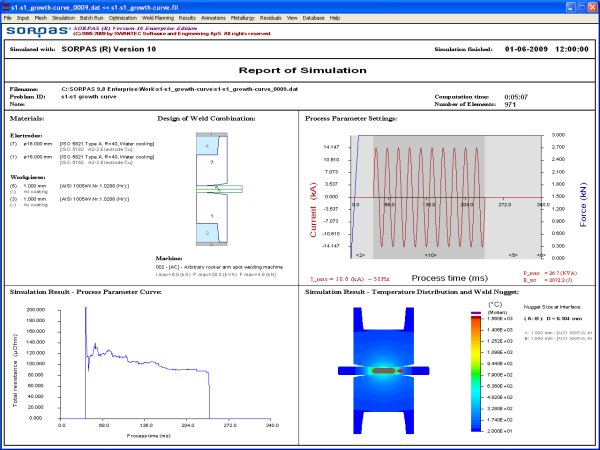

After each simulation, SORPAS® will generate a Report of Simulation

for documentation. Below is a typical report for a spot welding

simulation. In the upper part, it shows the initial welding conditions

including material combinations, geometry of electrodes and workpieces

as well as the welding process parameter settings. In the lower

part, it shows the main simulation results with a selected process

parameter curve, the final temperature distribution with the weld

nugget dimension in each workpiece.

|

The major industrial sectors applying resistance welding are listed

below.

The major industrial sectors applying resistance welding are listed

below.